Laser Cutting Services and Metal Component Manufacturing

Posted on December 27th, 2016 by vapro

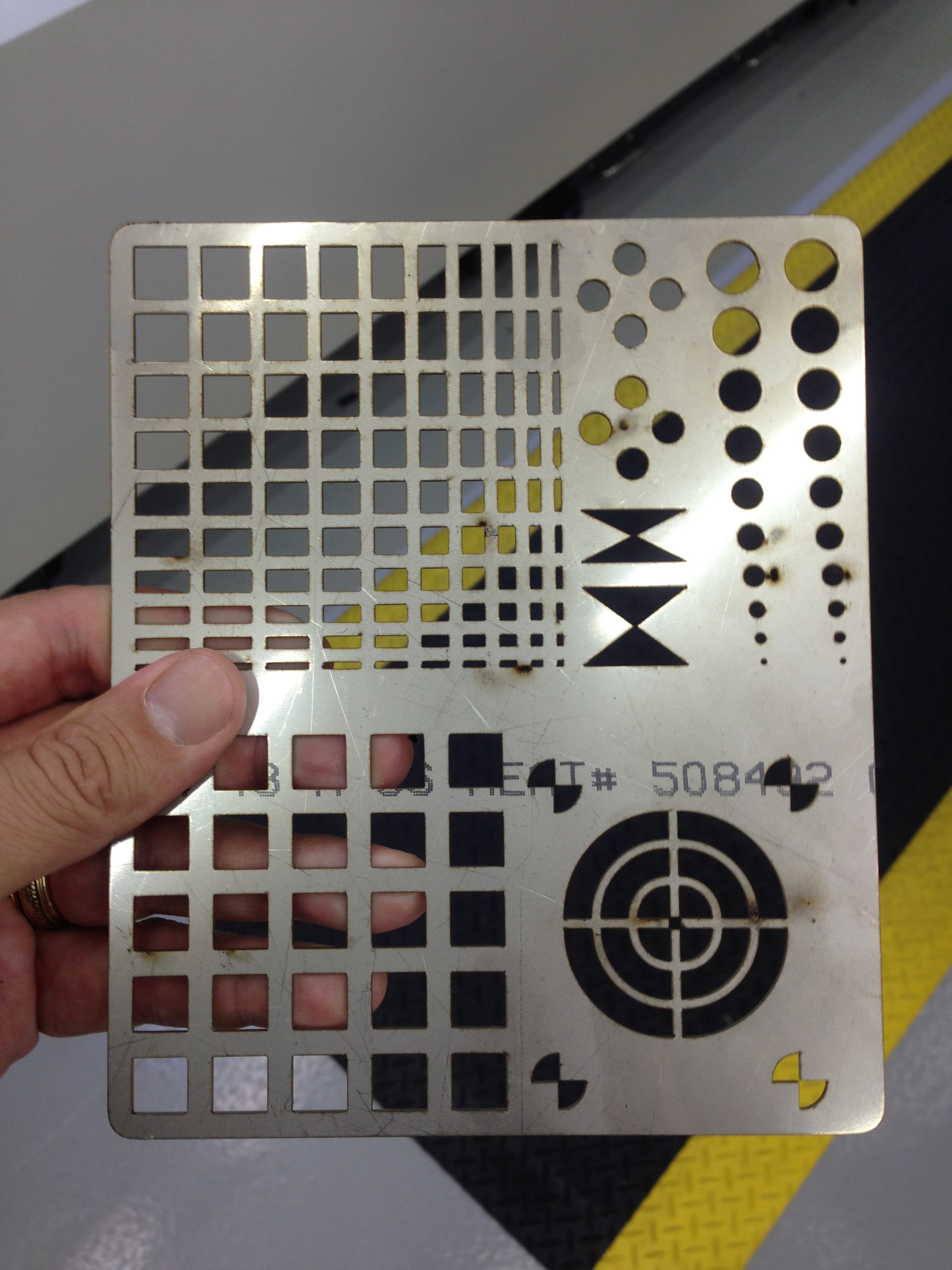

Laser cutting is a highly precise and efficient method of cutting metals. Laser cutters are computer directed which ensure a safer experience with less errors. Unlike traditional punch pressing, laser cutting offers many advantages. The level of precision and quality of edges are sharper and more pristine, the cuts are free of burrs and dust formations, and the amount of contamination to the material is reduced as well.

Fiber optic laser cutters are the latest generation of laser cutters, quickly replacing older CO2 lasers due to their revolutionary speed several times faster than older CO2 lasers. In addition, their lower cost of maintenance and operation, means we can produce parts much quicker and at a more competitive price.

However, not only do we have the right equipment, but just as importantly, we have the right people. With over 20 years in laser cutting experience with both CO2 lasers and now: our latest fiber laser, we possess the essential combination of both experience and cutting-edge machinery.

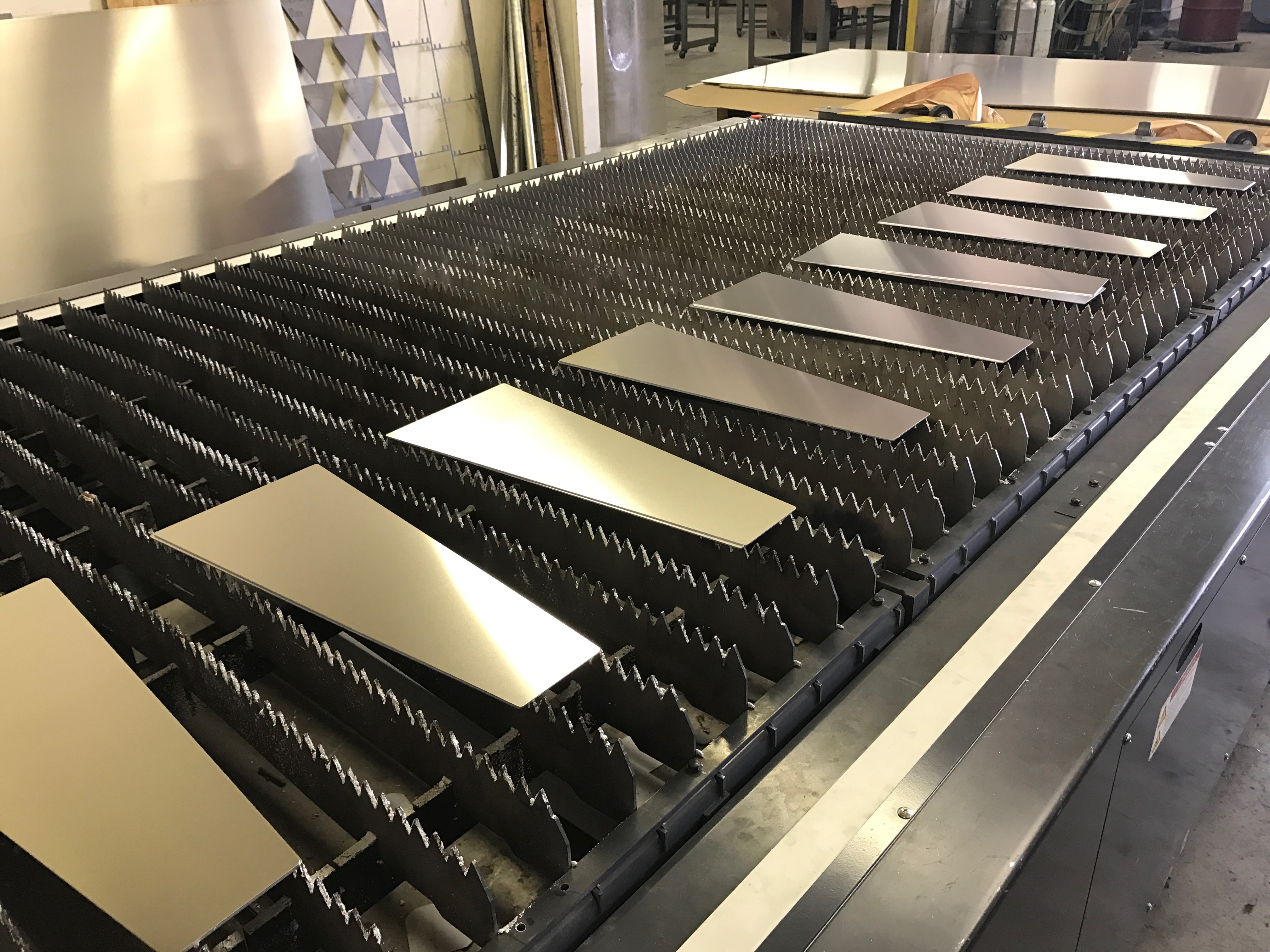

4000 Watt Mitsubishi Fiber Optic Laser Cutter

Purchased in 2017, Guzman Manufacturing employs a state-of-the-art 4000 watt Mitsubishi 3015eX-F40 fiber optic laser cutter.

Our machine allows us to cut the following material thicknesses:

- 1″ Mild Steel

- 0.5″ Aluminum

- 0.5” Stainless Steel

- 0.135″ Galvanized

- 0.375″ Brass

- 0.250″ Copper

Guzman Manufacturing works to provide the highest quality laser cutting services to meet the most rigorous demands from our customers. We have experience working with many industries, including:

- Hi Tech

- Telecom

- Mail sorting equipment

- Energy sector

- Defense

- Aviation electronics

- Construction

- And much more…

Contact us today for a quote, or to inquire further about our laser cutting capabilities and processes.